Kumquat with me

This week: The climate so far is…; Innovative tools; Steel by design; Pumping concrete; Those red bugs; Not everything is rosy; Kumquat with me;

It’s been another busy week for me, just trying and sometimes failing to keep ahead of the builders. They work extremely hard, even on Sundays!

I’ve been keeping an eye on the weather too. Trying to work out the best day to plant things, weed, spray and carry out similar garden tasks.

But with a very variable weather pattern, it has almost been “Open the curtains and see what the day is like” every single day.

The climate so far is…

WARM!

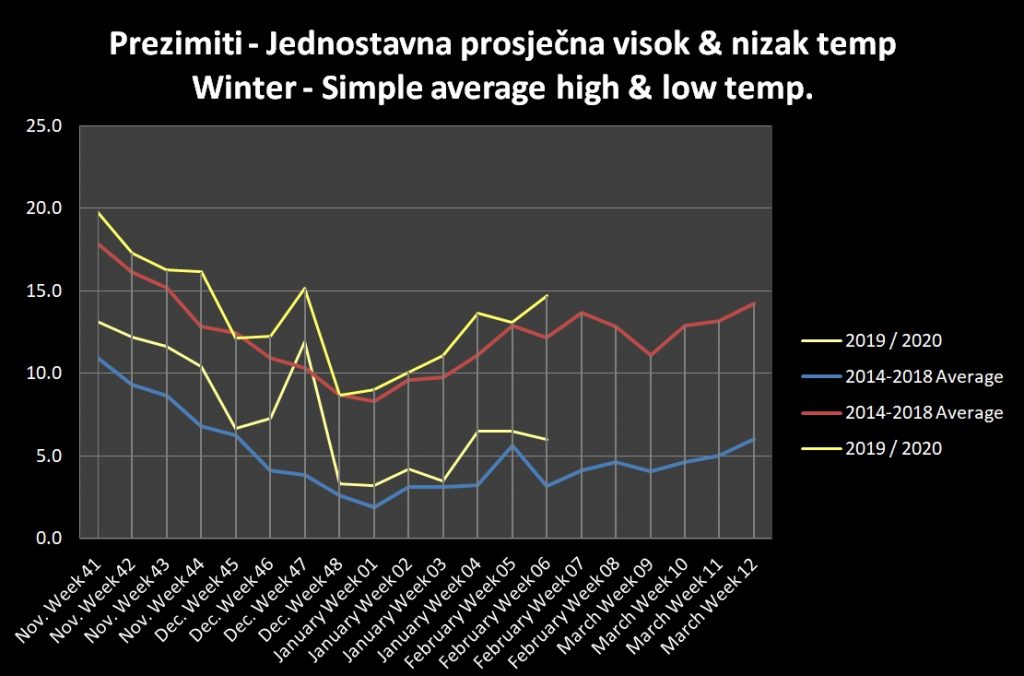

It was announced this week that January 2020 has been recorded as the warmest month of January, for the world, EVER!

Certainly my weather station has recorded above average daily temperatures, both the coolest and warmest in a 24 hour period. This seems to be the new “normal”.

We are already experiencing temperatures normally felt at the end of March, so we are six weeks ahead of the average.

Innovative tools

Just as I anticipated, the builders have been working to get ready for installing the workshop ceiling/1st floor this week.

Another of those strength features is a reinforced ring beam that runs around the top of the workshop walls. It takes a considerable amount of effort (and timber) to build the form-work for the beam, before the first concrete can even be mixed.

There are a number of pieces of builders equipment that I’ve not seen used anywhere else. A very neat device is used to tightly hold the form-work in place until the concrete sets.

Comprising four parts, a length of rebar, two tension locks and a screw tensioner, it is easy to use and very effective.

A long wall drill is used to pierce the wall blocks and the wooden formwork. A length of rebar is pushed through with a tension lock in place.

A second tension lock is slid onto the rebar and the screw tensioner is then wound on, locking the wooden formwork to the wall.

The tension lock is tightened with a couple of hammer blows and the screw tensioner is removed.

Concrete is then poured and vibrated into the void, around the reinforcing mesh. After 24 hours the pieces are easily removed and reused. The small holes that are left in the wall blocks will be covered later by plaster.

Steel by design

The amount of steel which has gone into the ceiling/floor structure is incredible. Aside from the connected ring beam a 18 cm mesh of shiny new steel was laid across the boards. Then lengths of rebar were laid diagonally and tied into the support pillars.

All the way round the old buildings, a rebait was cut into the walls and the mesh was extended into this gap. More steel was added in the shape of a fan to spread the load into the rebait.

Then more mesh was added on top, but with “legs” along each side, so it is raised off the boards giving a three dimensions box section to the floor.

I have installed all the utilities, electric conduit, insulated central heating pipes and water. This is between the steel reinforcing. I hope I will never need to access it!

All of this will be encased in 15 cm of concrete. There has been discussions about how the concrete will be delivered to the 1st floor level. While wheelbarrows are the traditional method – and the method used on the building base and foundations – the received wisdom is that pumped concrete, delivered quickly is the best method.

This is because the delivery is quick, (30 minutes or less) so the setting is more uniform and hence the concrete is stronger. It takes time for workmen to mix and wheelbarrow large volumes of concrete.

Pumping concrete

The builder had been unable to get a pump early this week. On the island we have some of the large three and four axle pumps, but they are too big to get up the lane to my home.

There are only a couple of small pumps and they are in demand, so with the steelwork finished, it was to be next week before the concrete was poured. Then on Thursday afternoon the builders were back. The pump truck was on its way!

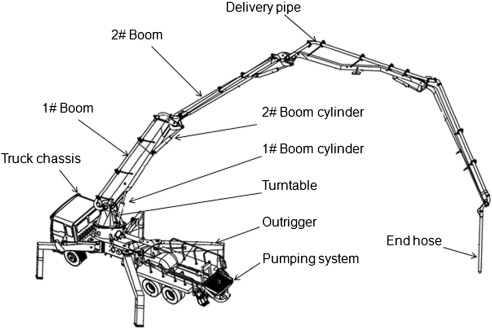

There is a lot of information available now about how these machines work.

A mixer reverses up to the pump and empties its drum into the hopper. Compressed air pistons then force the concrete along the delivery pipe to where it is needed.

Just getting up the lane was difficult. There is little room between the houses. The lanes around Dol were built for Donkeys, not trucks.

But there is a pinch point between my neighbours home and their vegetable garden.

No amount of manoeuvring would get the MAN through. So the driver tried to reach from where he could get.

That failed. Although the distance was +/- 30 meters, the boom was not long enough by about three meters.

So after repositioning, and supervised by the mayor of the village, the truck was inched as close as he could get.

With the boom extended and almost flat, the delivery pipe just reached the roof.

The delivery pipe wouldn’t reach into the corners, so the builders improvised with a wooden chute. The result was a success.

Eight tonnes of concrete were poured in less than 30 minutes to make the ceiling/floor, which together with probably a tonne or more of steel, means that the foundations will already be earning their keep.

The support structure required to hold up this weight of concrete is substantial.

A large number of jacking arms, thick baulks of timber and a network of wooden support beams all hold the wooden floor in place.

This in turn supports the steel reinforcement and then the heavy, wet concrete.

As the concrete dries, it will get a little lighter, but not substantially so.

Everything will now remain in place for four weeks to allow the concrete to set completely and gain maximum strength. So it will be a few more weeks before the doors and windows are fitted and I can start working inside.

Those red bugs

Some times all you need is a bit of lateral thinking.

I posted photos last week of the cute red bugs that I have all over my Madonna lilies. It was less than an hour and a half later that I received a message from one of my retired colleagues to tell me they were called Scarlet Lily Beetles, Lilioceris lilii .

They overwinter in the soil and emerge in the spring to mate and lay their eggs. Both adults and larvae eat the leaves of lily plants, leaving large holes in the leaves. Mine already have these large voids visible.

However, I have a lot of lilies which flower profusely, so I am not too worried.

Originally ranging from Europe to Asia, they are now considered an invasive pest in much of North America.

Now I know the name, I’ve been back through my books to see why I missed them. My Mediterranean Insect Encyclopedia doesn’t list them.

Although they are found in the UK, they are not in my Readers Digest Guide to Insects either. So it is all thanks to my colleague who did a Google search for “red bugs eating lilies”.

Sometimes you just need to use the simplest of search terms….

Not everything in the greenhouse is rosy

There has not been a lot of sun this week, but what we have had has been nice. As the sun rises earlier every day, so there are more heating hours in my small greenhouse.

With warm sun heating everything, it has been very pleasant in there. That has meant that I have already started watering the plants because the soil has been drying out.

When I had a look in the propagator, where I planted some Caper cuttings back in January, I saw that one of the cuttings had died. The stem has gone brown and was covered in mildew.

It has now been removed.

The remaining cuttings are still green, with some evidence of the buds starting to swell. Several leaves, towards the end of the cuttings had also been attacked by mildew, so I pinched them out as well, just to be sure.

The propagator has a base of moist sand with a built in heating element, that keeps the temperature at 20ºC. So with heat, light and copious moisture and humidity, fungus, mildew and “damping off“ are always going to be a problem.

I hope though that by reacting quickly, I have prevented the loss of all the cuttings.

This is my first attempt to propagate Capers though, so I am prepared for failure. Although not everything in the greenhouse is rosy, in the orchards things are looking up.

Kumquat with me

The branches on my Kumquat, Citrus margarita, are covered with ripe, orange fruit.

If you are lucky, you might find them in the ‘Tropical fruits’ section of your local supermarket.

The fruits are eaten whole, rind. pips and everything.

They have a very interesting taste because the rind is quite sweet but the flesh inside has a lemon flavour and is a little tart with a hint of cinnamon spice. In the mouth this mixture of flavours gives your taste buds quite a work out.

Although the Kumquat needs warm to hot summers, it also withstands winter cold and frost down to -8ºC, so it can be grown in a wide range of locations.

The Spruce Eats website lists seven ways to use Kumquats However I like the BBC Food recipe for poaching them in a honey & sugar syrup, then serving them topped with vanilla ice cream.

What I think I will try is a recipe for Candied Kumquats, something which is easy to do, quick and creates little mess.

Now if I had ducks, I could also feed the Kumquats to the ducks then I would have a ready meal, with self stuffed citrus… NRC

4 Responses

Marcy

Wow that building is looking great. And I remember a post when you thought this day would never come. Thanks as always for sharing.

Rick

Appears more than earthquake-proof. It should provide a cool retreat in the summer and a warm place in those cold months.

Branimir

Hi Norman,

I’m very glad to see such swift progress in the construction work.

Just a word of advice: don’t be surprised if the workers ask you to put a flag on top of the roof beams, once they put them in place, as that’s a custom in Croatia.

Galvanized Expanded Metal

This is a very nice project to share here, we appreciate your effort for doing this. Really you have done an amazing job with that building. I am happy to come across this blog, keep sharing such more articles,